A Mail deliveries

Order by 4 pm = delivery the next working day.

Free delivery

From CHF 100 purchase

-

MenuBack

-

Online Store

-

-

-

- Couverture

- Temperature control units

- Aids for chocolate

- Chocolate molds

- Praline fillings

- Chocolate ingredients

- Praline hollow body

- Chocolate colors

- Chocolate tattoos

- Chocolate packaging

- Bean to Bar

- Material for cutting chocolates

- Batons with Kirsch

- Airbrush for chocolate

- High Heels Accessories

- Textured films for chocolate

- Chocolate fountain & fondue

-

-

-

-

-

- Cakes Fillings & Ingredients

- Fondant & Marzipan

- Cakes tools

- Cake rings

- Silicone molds

- Decorative mats

- Baking pans for cakes

- Cake stand

- Cakes packaging

- Airbrush for cakes

- Sugar flowers accessories

- Cake Topper & Wedding Figurines

- Cakes dummies

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- Baking chocolate

- Glucose & Sorbitol

- Cocoa beans

- Cocoa nibs

- Monin syrup

- Champagne & Alcohols

- Freeze dried fruits

- Cake & cake glaze

- Flours & baking ingredients

- Chocolate coating & chocolate

- Milk powder

- Granules

- Nuts & Nougat

- Fruit puree

- Creams & Fillings

- Egg yolk & egg white

- Fruit powder

- Special ingredients

- Fondant & Flower Paste

-

-

-

-

-

-

-

- Punching, cutting & embossing

- Mixing bowls & whisks

- Chocolate material

- Thermometer & Burner

- Gloves & Protective Material

- Smoothing & Modeling

- Roll out bar

- Dough scraper & horn

- (Flour) sieves

- Brushes & Tweezers

- Cake turntable

- Spatula & Spatula

- Silicone embossing molds

- Insert strips & cake slices

- Measuring cup

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Schablonen & Stencils

-

-

-

-

-

-

-

-

-

-

-

Courses

-

-

- Current courses

- Praline courses

- Chocolate courses

- Chocolate kiss course

- Macaron courses

- Cake courses

- Baking courses

- Patisserie courses

- Ice cream course

- Guetzli, Cookie & Confectionery Courses

- Bread courses

- Pasta courses

- Apéro course

- Cooking courses

- Cupcakes courses

- Éclair course

- Courses in Zurich - Adliswil

- Children's courses

-

-

- Team Events

- Hen Night

- Retail Store

-

About Us

-

-

-

DirectionsDownload relevant PDF now.

-

-

-

Recipes blog

-

-

Recipes Blog

-

-

-

Shipping and Payment

-

- Online Shop

-

- Novelties

- Sale

- Gifts Cards

- Stencils & Stencils

- Chocolate and pralines

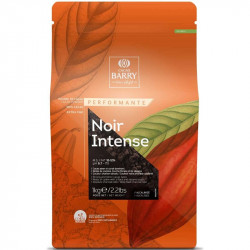

- Couverture

- Temperature control units

- Aids for chocolate

- Chocolate molds

- Praline fillings

- Chocolate ingredients

- Praline hollow body

- Chocolate colors

- Chocolate tattoos

- Chocolate packaging

- Bean to Bar

- Material for cutting chocolates

- Batons with Kirsch

- Airbrush for chocolate

- High Heels Accessories

- Textured films for chocolate

- Chocolate fountain & fondue

- Couverture

- Cakes & Pies

- Ice cream

- Bread

- Macarons

- Hearty

- Recipe booklets & books

- Cupcakes

- Dessert

- Cake Pops

- Edible decorations

- Fillings & Ingredients

- Glucose & Sorbitol

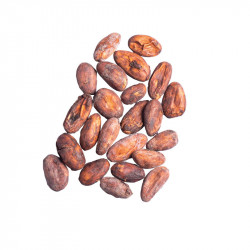

- Cocoa beans

- Baking chocolate

- Cocoa nibs

- Monin syrup

- Champagne & Alcohols

- Freeze dried fruits

- Cake & cake glaze

- Milk powder

- Flours & baking ingredients

- Chocolate coating & chocolate

- Granules

- Nuts & Nougat

- Fruit puree

- Creams & Fillings

- Egg yolk & egg white

- Fruit powder

- Special ingredients

- Fondant & Flower Paste

- Food Colors

- Auxiliary means

- Spouts & piping bags

- Fondant, marzipan, flower paste

- Bakeware

- Aprons & Potholders

- Cookie cutters

- Season

- Candles

- Party accessories

- Cocktail

- Cookie & cookie tins

- Tableware

Bean to Bar

Unterkategorien

There are 21 products.

Active filters

Bean to bar

The cocoa tree

The cacao tree is found mainly in the tropical rainforests, because there it has the best growing conditions as well as the optimal breeding ground. Close to the equator and 20° north/south in warm and humid zones is the best place for the cacao tree, outside this latitude it does not flower.

For a successful harvest, the trees should not be exposed to temperatures below 16 or above 35 °C, as they are very sensitive. They are also susceptible to various diseases. Cacao comes mostly from artificial cacao plantations, where it is protected from the sun by banana trees planted in between, as it prefers shade to the blazing sun. It grows five to eight meters high and requires mosquitoes and small flies for pollination. As a substitute for natural pollination, it can also be done manually. The flowers of the cacao trees bloom all year round, however ultimately only a small portion of them grow into cacao fruit.

For all these reasons, just ten countries produce 90% of the world's crop, with African countries such as Ivory Coast, Ghana, Nigeria and Cameroon accounting for the bulk of world production. Other important growing countries are Brazil, the Dominican Republic, Ecuador, Indonesia, Colombia, Malaysia, Papua New Guinea, Samoa, Togo and Venezuela.

Of course, there are several other growing areas that also offer high quality beans.

The fertilized flowers begin to grow relatively quickly already elongated fruit.

These have a hard shell reminiscent of a pumpkin, weigh about 300 to 500 g, are up to 25 cm long and contain about 40 seeds (cocoa beans). The ripe fruit bears a yellow, orange or red color depending on the variety, then the farmers separate the fruits from the tree, usually with a machete, and collect them.

When the fruit is opened, it quickly becomes apparent that the beans are held together by a white, silk-like tissue. At this stage, the pulp surrounding them (called pulp) tastes much like lychees, but is somewhat creamier in consistency.

As soon as the white cellulose tissue is separated from the beans, the beans, which are encased in white pulp, are ready for fermentation. The pulp serves as a nutrient in the fermentation process. In the growing regions, the raw beans together with the pulp are often used as a kind of chewing gum substitute, as the pulp has a sweet taste. The very bitter bean is not consumed in this process.

The fermentation of cocoa beans

Fermentation is an important process and lasts from three days to a week.

In this process, the beans with the pulp are often placed together in a box or pile, usually covered with banana leaves, and undergo a fermentation process.

Various transformation processes take place here, during which the fructose (the largest component of the pulp) begins to ferment.

During these days, the piles are rearranged several times, covered again and again, and reach a temperature of up to 50 °C under the leaves. The heat causes the liquid in the pulp to evaporate and at the same time prevents the beans from germinating. During this process, extremely important new aroma substances are created, which are essential for subsequent processing and have a massive influence on the taste.

The number of aerobic mesophilic germs is a measure of the general microbial load or contamination in a product. Aerobic mesophilic microorganisms represent bacteria, yeast germs and molds. The fact that cocoa beans have a high load of up to over 100 million colony-forming aerobic mesophilic units per gram has a completely natural reason.

With the help of yeast bacteria, the pulp of the cocoa fruit is fermented, converting the sugar into ethanol and later into acetic acid. Ethanol and acetic acid penetrate the cocoa beans, causing a chemical transformation. This is essential, because non-fermented beans cannot be used for high-quality chocolate.

As soon as the desired degree of fermentation is reached, the farmer starts the drying process of the beans. At the beginning of the drying process, the cocoa beans, which at this moment still have a high moisture content of about 50%, form an ideal breeding ground for microorganisms, which are additionally brought to the bean surface by animals, wind and people and multiply there. The drying process stops the fermentation process and reduces the growth of microorganisms.

The transport of cocoa beans

Drying the beans

Since the fermented raw cocoa still contains a large amount of water (about 50%) and there is a risk of mold and rot, it is exposed to the tropical sun for up to two weeks. It is usually spread out on the ground, on mats or boxes. The drying in this case causes a longer shelf life and also affects the taste.

The sunlight, in addition to the weight loss of about 50%, also makes the bean much browner and the flavor more towards chocolate.

Packing and shipping of cocoa beans

Packed in jute bags of about 60 kg each, the beans are brought to designated collection points and weighed, the quality is checked, and the beans are settled and sold at the respective state price. Here, too, there are cooperatives that sell the goods directly to the trader or processor, thus ensuring fair wages and sales for the farmers. The bags are labeled and sealed in each case to ensure traceability. During quality control, the beans are tested for irregularities regarding fermentation, foreign substances, foreign bodies, etc., as the aim is to guarantee the export of high-quality cocoa. The cocoa beans are loaded in large containers and from there they are shipped all over the world and distributed to the chocolate manufacturers.

Cleaning the beans

When the cocoa beans finally arrive at the factory or the chocolatiers after a long transport, various foreign bodies are often found in the bags despite the quality control. This is because the cocoa is harvested, collected, packed and shipped in different villages and tribes, where the people also live and work. Since the working environments are not sterile factories, it may well happen that various foreign objects such as dust, sand, wood, glass, stones and everyday objects like children's toys or coffee beans are found in the bags. These are removed with the help of sieves, magnets and air currents. At the chocolatier itself, the sorting out is mostly done by hand and with the help of the human eye.

Processing the beans into chocolate

In total, it takes about ten steps to turn the cocoa bean into delicious chocolate. After harvesting, fermentation, drying and transport, cleaning and thermal pretreatment, the beans are roasted, broken and shelled.

The final steps then include cocoa nib refining and grinding. After the grinding of the beans, the production of cocoa powder and the production of chocolate part ways.

Make your own chocolate from A to Z in our course

Would you like to dive deeper into the world of chocolate and learn more about the different cocoa beans? In our Bean to Bar course you will make your own couverture. "Bean to Bar" refers to the process of making chocolate from the raw cacao bean to the finished processed bar.

Bean to Bar Courses

Thomas Ramseier (course leader of the Bean to Bar courses) did his apprenticeship as a food technologist at Lindt & Sprüngli, where he was able to learn all the steps of chocolate production and processing in detail. The production of the couverture, which went from the processing of the bean to the mixing of the various ingredients to the conching process, was an important station of the training and gradually passed into the blood of the chocolatier with the tonnages produced.

Since then, the passion for chocolate has not let go of Thomas Ramseier and he has repeatedly traveled to the countries of origin of the cocoa beans and continuously expanded his knowledge. Through his experience from the ground up as well as the innovative knowledge gained as a home chocolatier, you can count on an experienced specialist in this course, who will take on the subject with a lot of joy and knowledge and thus equip you to become a home chocolatier yourself!

For more information on our Bean to Bar course, please visit our website at www.minischoggi.ch under Courses - Bean to Bar Course.